Project Information

Partner:

GE Johnson

Project Type:

Healthcare

Schedule Acceleration:

2 Months

Cost Savings:

$1 Million Dollars

Project Summary

Building Better. Zero Compromise.

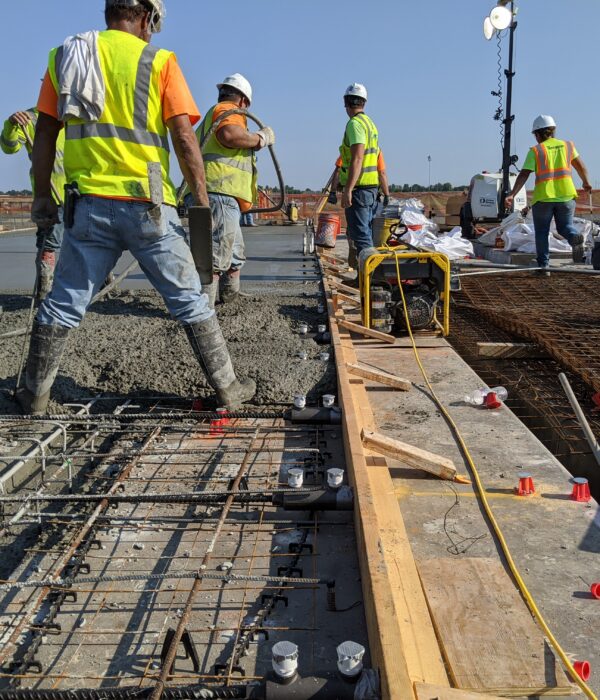

At AdventHealth Overland Park, the project team was up against a tight schedule and the complex logistics of traditional pour strips. By switching to PS=Ø, they gained a critical advantage—accelerating the project by 2 months and eliminating the need for backshoring entirely.

Without the delays and rework caused by pour strips, trades gained earlier access, sequencing improved, and the entire jobsite operated more efficiently. The removal of backshoring also created safer, cleaner work areas and reduced labor and material costs for the contractor.

AdventHealth Overland Park is a strong example of how PS=Ø clears the path for faster, safer, and more coordinated builds—driving real results without compromise.

Benefits Delivered:

- Eliminated Traditional Pour Strips

- 2+ Months of Acceleration

- Increased Jobsite Efficiency

- Eliminated Backshoring

- $1+ Million in Cost Savings

- Improved Jobsite Safety