Project Information

Weis Builders

Hospitality

2 Months

$1 Million Dollars

Framing Faster. Building Safer.

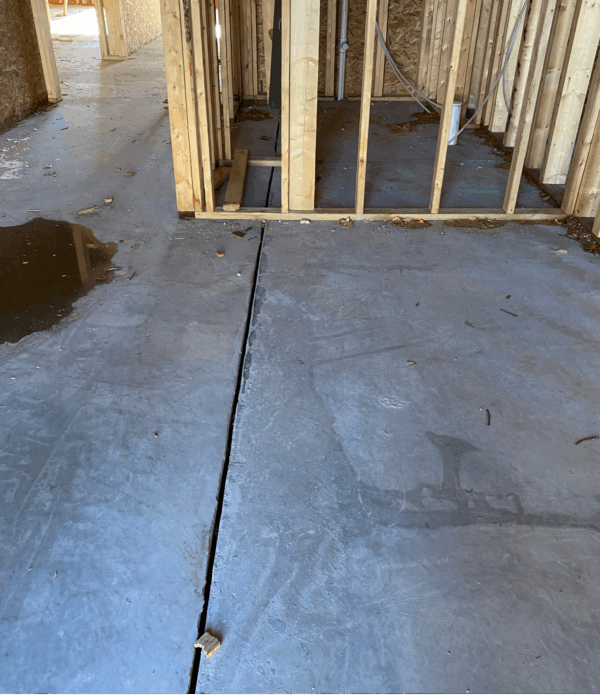

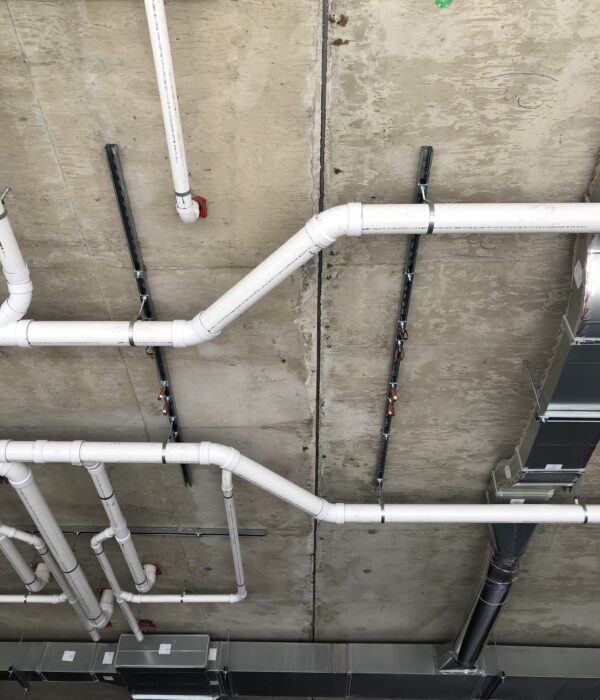

At the Even Hotel in Rochester, MN, the team faced a familiar challenge: getting framing started without being delayed by traditional pour strips. By switching to PS=Ø, they unlocked a key advantage—allowing framing crews to start 45 days sooner than with conventional methods.

This schedule gain proved critical in keeping the overall project on track. PS=Ø eliminated the delays, safety hazards, and rework typically associated with pour strips—making the site safer and more efficient for everyone.

Tony R. of Weis Builders shared: “By using PS=Ø couplers on our project, we were able to save time by starting our wood framing 45 days earlier over the pour strip. Safety was another benefit because we only had a small joint with less formwork and reshoring compared to a 4-foot wide strip.”

From accelerating trades to improving site safety, PS=Ø helped the Even Hotel team deliver a cleaner, faster, and more streamlined build—without compromise.

Benefits Delivered:

- Eliminated Traditional Pour Strips

- Accelerated Framing and Schedule

- Increased Jobsite Efficiency

- Eliminated Backshoring

- $1M in Project Overhead Savings

- Improved Jobsite Safety