A New Consideration in the Design of Expansion Joint Spacing

Existing/Current Consideration for Expansion Joint Location Design

There is only one reason expansion joints exist, that is volume change of construction materials. For most commercial enclosed buildings, volume change is from shrinkage of concrete, expansion, and contraction due to material thermal changes occurring during the construction of a building. What might this look like if there existed a strain relief joint (SRJ) that could eliminate these items by accommodating them during the construction phase?

All buildings are subject to expansion and contraction, no matter what materials they are made of including wood, steel, and concrete structures. This volume change is due to a number of physical characteristics, including temperature change, moisture changes (i.e. humidity, curing, drying) and load changes (i.e. post-tensioning and other load changes) causing elastic volume change and creep. All of these must be considered from the start of construction to final use. This article will deal with steel or concrete frames having concrete floors.

This issue of volume change has been determined to require a solution particularly in buildings having larger footprints. The resistance to volume change is often discussed as restraint to shrinkage (RTS). This will cause severe serviceability issues , due mostly to the effects of cracking, with long term effect of reducing the useable life of the building.

The solution normally is to include at least one or more expansion joints. These are joints that structurally separate the building into two or more separate buildings, structurally. Each building between expansion joints has its own independent structural system for vertical and lateral loads. Not only are expansion joints architecturally undesirable, they are costly in that the finished joint is expensive, so is the extra beam and column at each joint. Further, if shearwalls are used to resist lateral loads, two additional shearwalls will be required for each expansion joint.

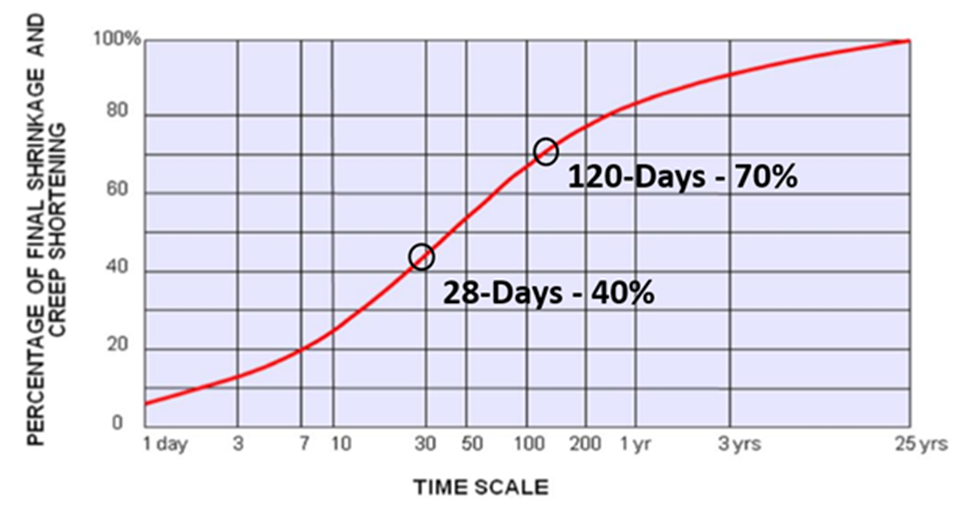

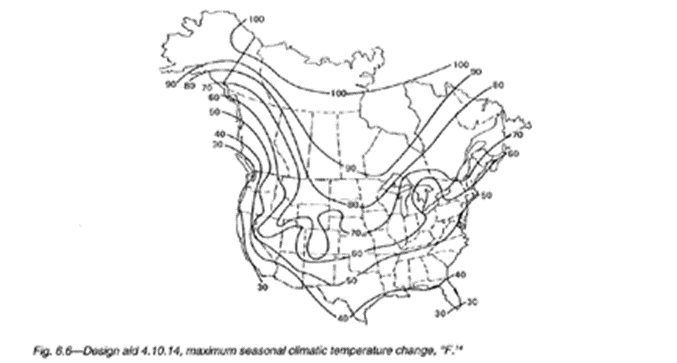

There are two types of volume change to be considered. Some volume change is permanent and some is variable. Concrete shrinkage is the primary contributor to the permanent volume change see Figure 1. Whereas temperature is the primary contributor to the variable volume change. For enclosed buildings, the temperature change to be considered is the extreme outside temperature during the construction period see Figure 3.1.

Shrinkage of concrete starts at the time of casting and changes with time as see in Figure 1. This solution can be partially or near fully dealt with by using pour strips or leave-outs for either reinforced concrete (RC) and post-tension concrete (PT). As can be seen from Figure 1, the often required pour back time of the traditional pour strip is 28 days, only 40% of the shrinkage has occurred. At about a year, 85% of the shrinkage has occurred. Influencing a shorter strain relief time (i.e. pour strip – pour back) in the construction schedule, where the traditional gap delays completion of mechanical, electrical, exterior envelopes, and other finish items.

Figure 1 Concrete Shrinkage vs. Time

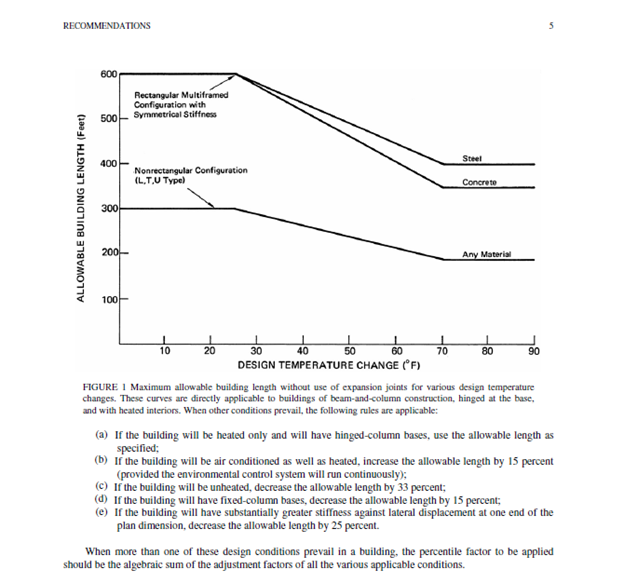

Figure 2 Building Length Between Expansion Joints, National Academy of Science Report No. 65

From the Report No. 65 reference, 600 feet is the distance between expansion joints for a heated symmetric building with hinged base of columns. If air-conditioned increase by 15% (i.e. 690 feet). If air-conditioned but columns fixed the decrease by 15% (i.e. back to 600 feet).

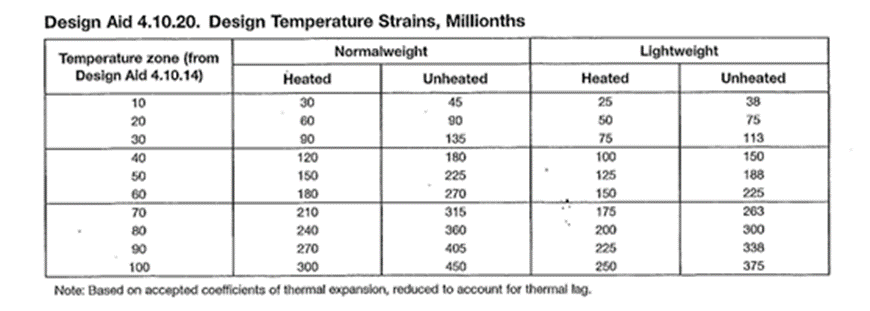

To calculate the expansion joint requirements, appropriate temperature data can be found in Appendix B of the Technical Report No. 65. There are a number of methods available to calculate shortening. The most popular methods are:

- ACI 209 Method

- PCI Design Aid Method

- Simplified Method

These methods all can be used to estimate the shrinkage shortening. As can be seen from Figure 1, if it were practical to let the shrinkage shortening freely occur for a year, without interfering with the construction schedule, there would be very little shrinkage shortening left to occur. The small amount remaining would not cause much future cracking or serviceability issues.

After the building is environmentally conditioned (i.e. heat and cooling) any change in temperature is no longer a factor contributing to building volume change. It is only during construction that, when the thermal envelope is incomplete, that it is critical.

Figure 3.1 Temperature Aid for PCI Method

Figure 3.2 Aid for Calculating Temperature Strain by PCI Method

Figure 4 Garage Building Length Between Expansion Joints

In the case of a parking garage with larger footprints (i.e. more than 300 feet), thermal loads (i.e. changes in temperature) will always be a factor to be dealt with by including an expansion joint. It should be noted that less shrinkage keeps the expansion joint mostly affected by temperature and less affected by shrinkage. Leaving the pour strip open longer helps provide for this.

The PTI reference states “PTI recommends for expansion joints and expose parking structures depend on whether temporary pour strips will be provided to alleviate other volume changes change affects during construction. The distance between expansion joints in the structure provided with temporary pour strips can increase up to 40% based on practical experience.”

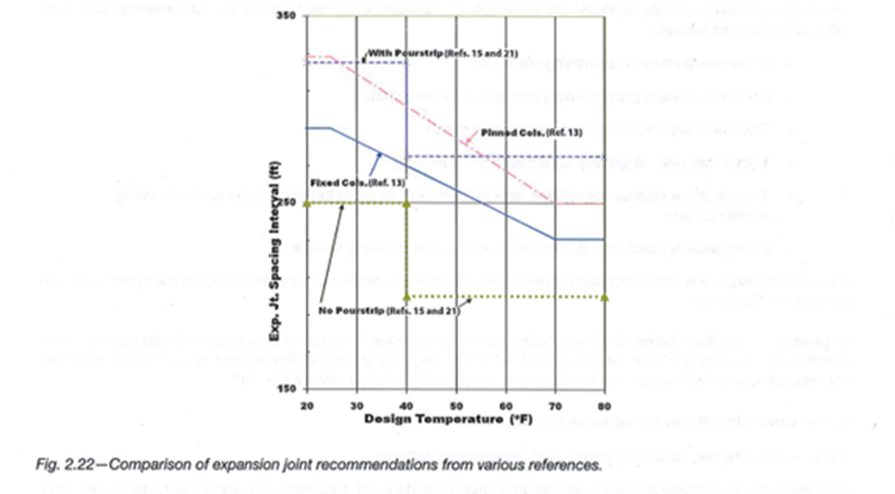

Figure 4 (i.e. Figure 2.22 PTI reference) compares expansion joint recommended recommendations from various references.

For crack mitigation philosophy, PTI has several recommendations:

“License design professionals (LDP‘s) routinely employ a number of details in their designs to limit the effects of RTS by temporarily and sometimes permanently minimizing restraint. A few methods for RTS crack mitigation are discussed hear in. These methods are applicable for conventionally reinforced and post tension members alike and are listed as follows:

Improved layouts of restraining elements;

Concrete mixture, proportioning, and specialty admixtures;

Structural separation between building sections;

Temporary pour strips and construction sequencing;

Temporary and permanent release details or release devices between slabs and restraining elements; and

Other detailing such as reinforcement and post-tensioning layouts.”

A New Consideration for Expansion Joints

PS=Ø® Mechanical Reinforcement Splicing System

For fully conditioned buildings, expansion joints are only necessary because of material volume changes during construction. If this could be changed, eliminate, or accommodated during construction, the need for expansion joints would be eliminated or for sure be minimized. Further, all the previously discussed calculations become irrelevant if the volume changes can be accommodated during construction and the structural parts reconnected before building completion.

The latest PTI publication “Restraint Cracks and Their Mitigation in Unbonded Post-Tensioned Building Structures” provides good guidance on the problem but only discusses current (i.e. existing technology) solutions, of which many are impractical to apply. Unfortunately, timing of the latest PTI publication may not have allowed to inclusion of the PS=Ø® Mechanical Reinforcement Splicing System, which is revolutionizing how professional designers will consider expansion joints and pour strips.

The PS=Ø® Mechanical Reinforcement Slicing System utilizing a modification improvement on a proven technology, originally invented to eliminate traditional pour strips in concrete construction and strain relief from other restraint to shrinkage (RTS) structural connections. Now the PS=Ø® can be used to accommodate these critical destructive volume changes during the construction phase and eliminate and or reduce expansion joint spacing.

Using the PS=Ø® mechanical reinforcement slicing system can radically change how expansion joint spacing is viewed and designed by the industry. By utilizing the PS=Ø® system not only can many expansion joints be eliminated, the final concrete product will be improved, be more cost effective and improve the construction schedule.

The majority of the shrinkage is completed during the construction cycle by leaving the PS=Ø® joint un-grouted (i.e. in a strain relieving state) until after the building is temperature controlled. This might often be near a year after the concrete floors have been cast, on either a steel or concrete frames. Since the joint normally opens to less than ½ inch and designed at the appropriate location requires no shoring and there is no interruption of the construction schedule. The PS=Ø® couplers and joint can be grouted just before floor finishes must be applied.

This process eliminates 70% to 85% of the volume change associated with concrete shrinkage and almost all temperate related volume changes.

References:

1 ACI Committee 209, “Prediction of Creep, Shrinkage ,and Temperature Effects in Concrete” (ACI 209), American Concrete Institute, Farmington Hills, MI, 2019.

2 ACI Committee 318, “Building Code Requirements for Structural Concrete and Commentary” (ACI 318), American Concrete Institute, Farmington Hills, MI, 2019.

3 Brady, Mathew D., “Expansion Joint Considerations for Buildings,” Modern Steel Construction, May 2011

4 Federal Construction Council, 1974, Technical Report No. 65, 1974, Expansion Joints in Buildings, National Research Council, Washington , D.C.

5 Fisher, James M., “Expansion Joints: Where, When and How,” Modern Steel Construction, April 2005

6 PTI Committee DC-20, “Restraint Cracks and Their Mitigation in Unbonded Post-Tensioned Building Structures” (PTI Committee DC-20.2-22), Post-Tensioning Institute, Farmington Hills, MI, 2022.

7 Reigstad, G.H.; Reigstad, J.G.; and Reigstad, J.M., “Designing for Construction Productivity and Safety,” Concrete International, V. 43, No. 6, June 2021, pp. 51-55.

8 Reigstad, G.H.; Reigstad, J.G.; and Reigstad, J.M., “Pour Strips Often Overlooked and Misunderstood,” Structures Magazine, December 2021, pp. 36-39.