POUR STRIP IN REINFORCED CONCRETE

Volume Change in Reinforced Concrete

Steel reinforced concrete is formed by a process of casting wet concrete around a reinforcing bar system. Steel reinforced concrete, as known today, has be used for over one-hundred years. Prior to steel reinforcing bars in concrete spans in elevated concrete floor and beams were very short and mostly used in compression structures (i.e. arches).

A definition of reinforced concrete is concrete in which steel bars are embedded in concrete in such a manner that the two materials act together in resisting forces after the concrete has cured. The reinforcing steel like rods, bars, or mesh resist tensile forces while the concrete resists compressive forces in a concrete structure. Plain concrete in flexure resists very minimal external forces through tension in the concrete. Unfortunately, most concrete cracks and no tension forces can be developed across a concrete crack. Compression can be developed, in cracked concrete, as the crack is closed. Thus, compression structures like arches work well without steel reinforcement, dating back to the Romans or further, but otherwise is unsuitable in most structural applications. For reinforced concrete flexural elements, the tensile strength of the steel reinforcing and the compressive strength of concrete work together to allow the member to sustain these stresses over considerable spans. The invention of reinforced concrete in the 19th century revolutionized the construction industry, and concrete became one of the world’s most common building materials.

Pour strips in reinforced concrete are needed because of shrinkage of the concrete and thermal loads.

Allowed to shrink with no restraint, there is no cracking in concrete. But in all cases, there is some form of restraint caused by vertical elements, necessary for both vertical support for gravity loads and lateral load resistance for wind loads and seismic loads.

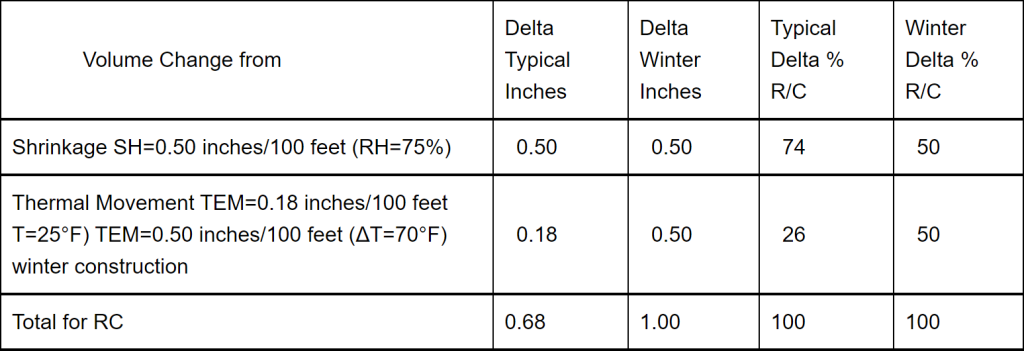

Shrinkage of the concrete and thermal volume changes caused by temperature changes are the significant contributors to volume change in reinforced concrete. During more extreme temperature change, shrinkage and thermal can each contribute 50% of the volume change. The shrinkage itself is permanent and reduces with time. Thermal is variable with changes related directly to temperature of the element considered.

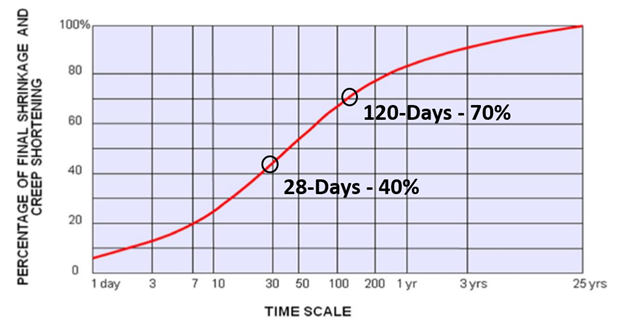

Concrete Shrinkage vs Time

As can be seen from the time scale, figure that all the shrinkage will take as long as 25 years, but at the traditional 28-day strength only 40% of the shrinkage has occurred. It should also be noted that just over 100 days 70% of the shrinkage has occurred. It is clear that the longer the relief strip is left open the less shrinkage the structure is required to absorb over time. The result is less cracking the longer the leave-out is left open.

Concrete Volume Change Post-Tension Concrete