POUR STRIP IN P/T

Volume Change in Post-Tension Concrete

Post-tension concrete is formed by a process of casting wet concrete around an unstressed wire or strand system and then stressing the wire or strand system after the concrete has reached specified strength (e.g., cured to a set specification). This is referred to as an unbonded system. For example, post-tensioned concrete can have a wire or strand system which has a wire or strand enclosed in a duct (e.g., pipe, conduit, etc.). Concrete is formed around the duct and the concrete sets and cures. Then, the wire or strand is stressed and grout material (e.g., a mixture of cement, sand, aggregate, and water) is pumped into the cavity surrounding the wire or strand. This is referred to as a bonded system. The grout material bonds the wire or strand to the duct, and the duct is bonded to the cured concrete. Thus, the stress applied to the wire or strand can be transferred to the concrete.

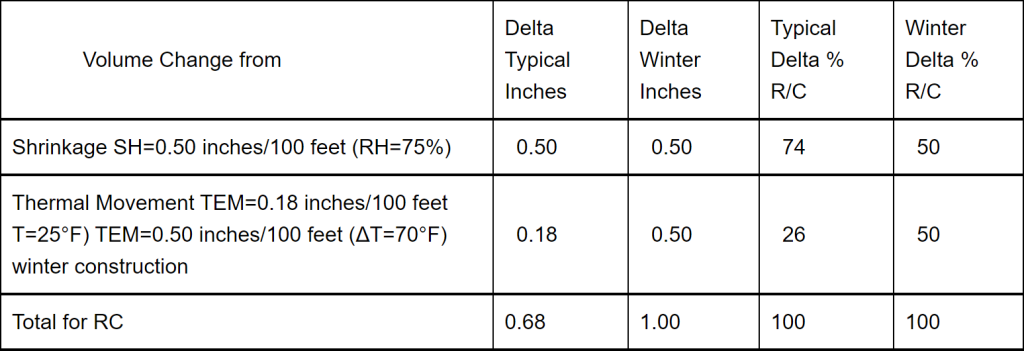

Pour strips in post-tension concrete are needed due to volume change in the concrete. The specific causes are shrinkage of the concrete and thermal volume changes related directly to temperature changes of the concrete. In post-tension concrete there also is elastic shortening and creep. The majority of volume change is due to shrinkage of the concrete, which is permanent and thermal volume changes, which are variable with temperature.

Allowed to shrink with no restraint, there is no cracking in concrete. But in all cases, there is some form of restraint caused by vertical elements, necessary for both vertical support for gravity loads and lateral load resistance for wind loads and seismic loads.

In addition to shrinkage and thermal volume changes, post-tensioning causes both elastic shortening, and creep which contribute to less than 20% of the entire volume change. The other 80% is due to shrinkage of the concrete and thermal changes due to temperature change. The shrinkage itself is permanent and reduces with time. Thermal is variable with changes related directly to temperature of the element considered.

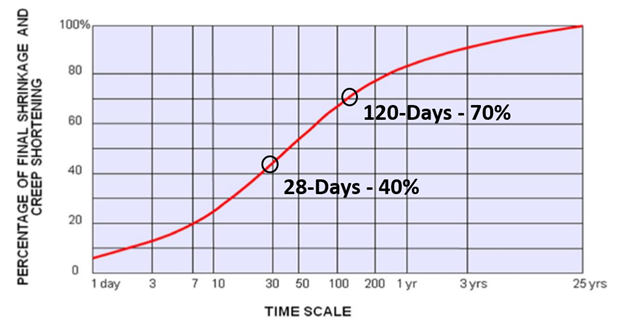

Concrete Shrinkage vs Time

As can be seen from the time scale, figure that all the shrinkage will take as long as 25 years, but at the traditional 28-day strength only 40% of the shrinkage has occurred. It should also be noted that just over 100 days 70% of the shrinkage has occurred. It is clear that the longer the relief strip is left open the less shrinkage the structure is required to absorb over time. The result is less cracking the longer the leave-out is left open.

Concrete Volume Change Post-Tension Concrete