PS=Ø® 101: Everything You Need To Know About Pour Strip Zero

Part 1 - Eliminating Pour Strips

PS=Ø®

Why Pour Strips?

When a concrete floor slab cures, it undergoes significant volume change. If restrained (connected to shear walls, columns, etc.), it will be restricted from its natural volume change. The longer a floor slab is, the more volume change it will experience. Geometry also plays a significant role in restraint because a building’s configuration determines where stiff elements are placed. The larger, more complex a footprint is, the more restraint will be present.

Engineers refer to the volume change/restraint problem as restraint to shortening (RTS): concrete shrinks (shortens) and anything it’s connected to will restrain it, causing it to crack. To solve this RTS problem, pour strips (Figure 1), otherwise known as leave-out strips, delay strips, pour-back strips, etc., have been used by engineers for decades to solve the RTS problem.

Why PS=Ø®?

Reduce Costs

Accelerate Construction

Improve Safety

Quality Concrete

Win-Win

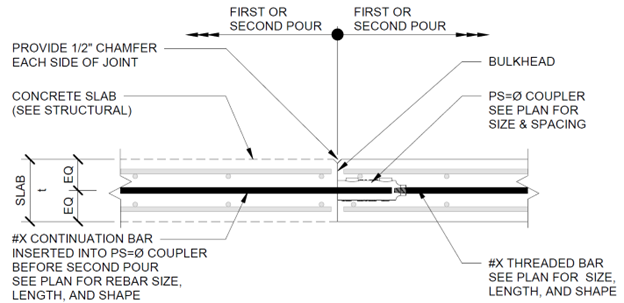

Slab to Slab Application

In this application (Figure 3) either side can be poured first but if it’s PT, stressing of the second pour must happen at the outside slab edge. To see our installation video of this application Click Here.

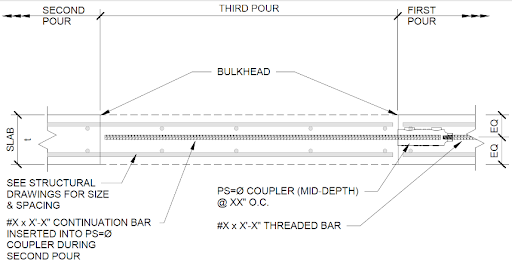

Slab to Slab with a Temporary Stressing Strip Application

What if you can’t get at the outside edge of the second slab to stress the tendons in PT? We have a solution for that, which is commonly used in subterranean conditions. In this application (Figure 4) either side can be poured first but after both pours are done and tendons stressed, the third pour (the stressing strip) can be placed right away. The joint will always open up next to the coupler

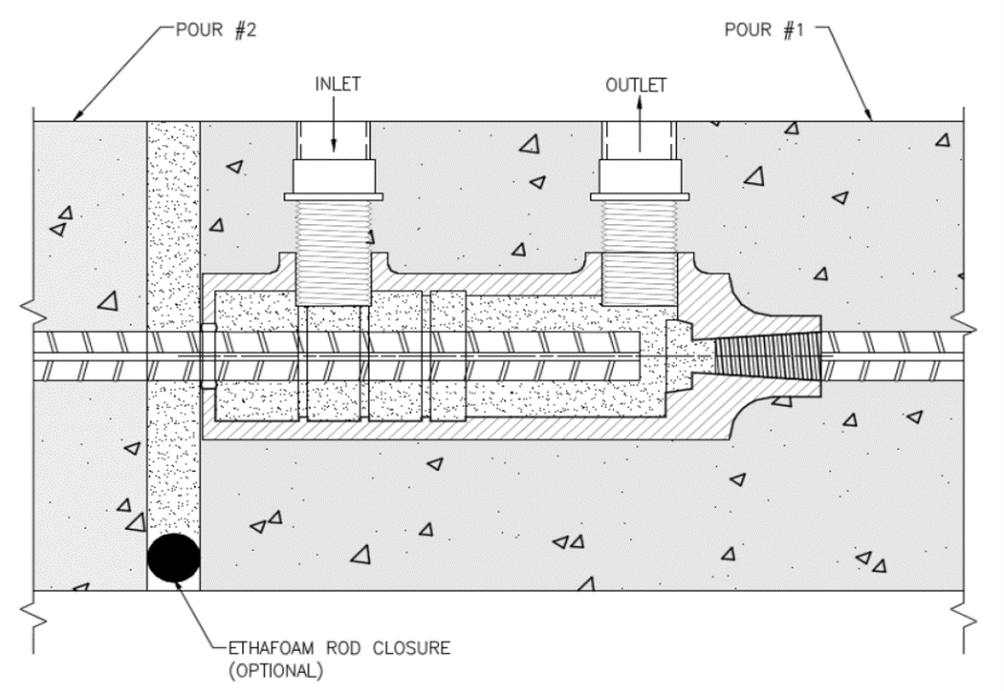

Grouting the PS=Ø® Relief Joint and Couplers

The length of time between placing the slabs and grouting the joint and couplers is still specified by the Engineer of Record (EOR), although we recommend waiting as long as possible to achieve the highest level of quality. There will be a time when grouting the system is critical, but it’s typically beyond standard pour strip leave-out times. Trades can easily work across an ungrouted system with no issues, i.e., mechanical, electrical, plumbing, wood-framing, cold-formed-metal-framing (CFMF), etc. can be installed with ease (Figure 5). However, the system should be grouted prior to installing any rigid materials across the joint. For instance, grouting should take place prior to the installation of exterior wall systems consisting primarily of glass, precast concrete, or concrete masonry units (CMU) that are connected to the slab and are not designed for horizontal movement.