PS=Ø® 101: Everything You Need to Know About Pour Strip Zero

Part 3 – Eliminating Expansion Joints

This is Part 3 of our four-part blog series about PS=Ø®, where we discuss all of the system’s various applications. In Part 1, we focused on the function of pour strips and how to eliminate them with PS=Ø®. In Part 2, we reviewed how PS=Ø® eliminates wall leave-outs. In part 3, we will discuss expansion joints, why they’re necessary, and how the PS=Ø® system can be used to eliminate them.

Recap: What is PS=Ø®

PS=Ø® stands for pour strip zero and is a mechanical reinforcing splice system that eliminates pour strips, wall leave-outs, and expansion joints while maintaining structural integrity and allowing for volume change. It utilizes proven coupler technologies recognized worldwide, featuring a thread on one end and a grout-filled sleeve on the other. The system is an ACI 318 code compliant full-tension mechanical Type 1 and Type 2 rebar splice, is ICC approved, and is made in the USA.

Why Expansion Joints

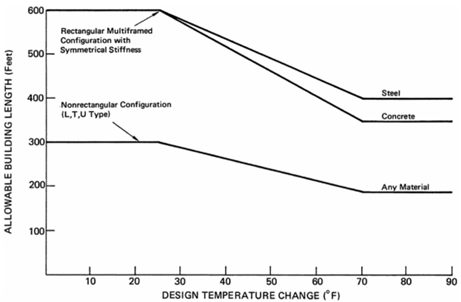

In 1974 the Building Research Advisory Board of the National Academy of Sciences (NAS) published Federal Construction Council Technical Report No. 65: Expansion Joints in Buildings. In this report expansion joints for both steel and concrete structures are recommended for buildings when they get long enough depending on shape and temperature change (Figure 1). Expansion joints are designed to handle structural movement in two ways: First, they eliminate the adverse effects of shrinkage in concrete structures. Second, they allow for thermal contraction or expansion in both steel and concrete structures.

Figure 1. Allowable Building Lengths vs. Temperature from Federal Construction Council Technical Report No. 65: Expansion Joints in Buildings

For an enclosed building, the largest thermal expansion or contraction occurs during construction, prior to the completion of the building envelope and subsequent temperature regulation. Once the building is enclosed and the temperature is regulated, there is very little need for an expansion joint. Conversely, if the structure is not enclosed and temperature cannot be regulated, an expansion joint is needed. For example, a parking structure exposed to the elements will always require an expansion joint.

The Problem with Expansion Joints

Expansion joints, like pour strips, are a nuisance and very expensive. Architectural joints used at expansion joints (Figure 2, 3) are an eyesore, require duplicate, separate structural systems and create additional problems. Expansion joints can range in width from a few inches to feet, depending on the building stiffness and anticipated lateral movement under wind and seismic events.

Beyond the cost of the architectural joint itself and additional structural systems, expansion joints are very expensive to maintain, and often fail and need to be replaced over time. Just like pour strips, expansion joints are seen as a necessary evil in the construction industry.

Figure 2. Typical Building Floor Expansion Joint.

Figure 3. Typical Building Floor-Wall Expansion Joint.

How PS=0 Eliminates Expansion Joints

Like pour strips, expansion joints allow for movement between two adjacent structural elements. But unlike pour strips, expansion joint issues continue after construction is complete. PS=Ø® can replace expensive expansion joints by connecting two adjacent structural elements where the expansion joint would normally be. After the concrete has undergone much of its volume change and the building is enclosed and kept at a regulated temperature, the PS=Ø® system can be grouted. After grouting, PS=Ø® creates structural integrity, transferring both vertical and horizontal loads.

Used in this way, PS=Ø® effectively eliminates the need for expansion joints, the huge expense, constant maintenance, and the need for replacement — thus eliminating all the problems that accompany expansion joints.

Eliminating Expansion Joints in Concrete Structures

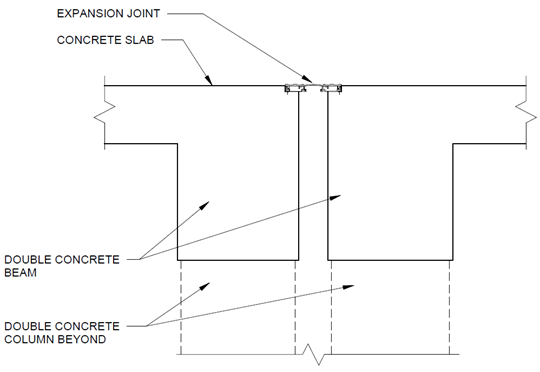

A typical expansion joint in a concrete structure consists of double structural elements, bridged by the expansion joint itself (Figure 4). In this detail, there are beams and columns on both sides of the expansion joint.

Figure 4. Typical Conventional Structural Expansion Joint in Concrete Structure

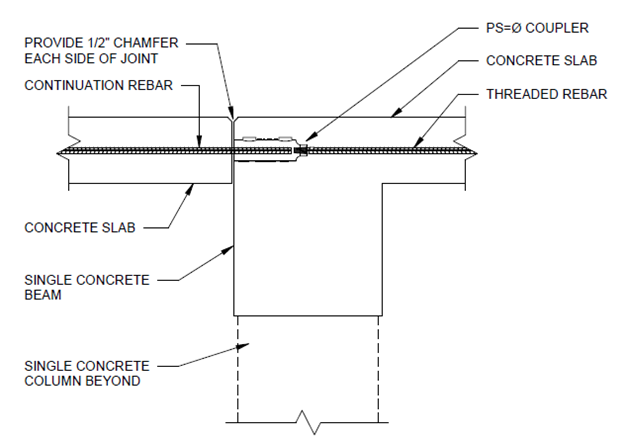

PS=Ø can easily be placed in the slab and used to connect the two adjacent concrete structures without the need for double beams and columns (Figure 5). It’s easy to see how PS=Ø® simplifies the structure, thus eliminating all the additional expenses and architectural issues created by expansion joints.

Figure 5. Typical PS=Ø® Structural Expansion Joint Eliminated in Concrete Structure

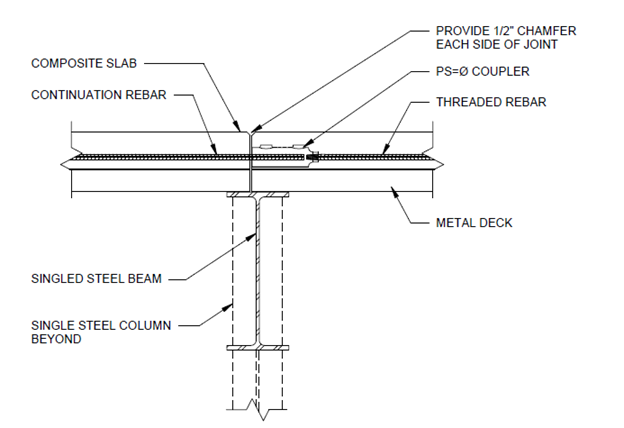

Eliminating Expansion Joints in Composite Steel-Concrete

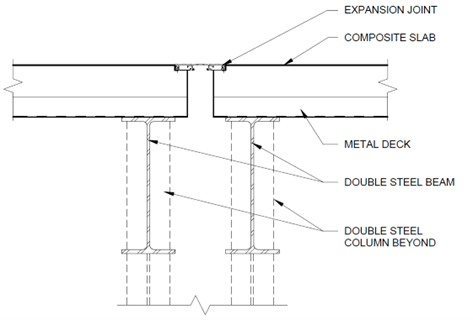

Composite steel-concrete structures consist of steel beams and columns, and a concrete-filled metal deck. Just like in a concrete structure, a typical expansion joint in a composite steel-concrete structure has double structural elements, bridged by the expansion joint itself (Figure 6). In this detail, there are beams and columns on both sides of the expansion joint.

Figure 6. Typical Conventional Structural Expansion Joint in Steel Frame Structure with Concrete Floor

PS=Ø® can easily be used to connect the two adjacent structures, through the concrete-filled metal deck without the need for double beams and columns (Figure 7). As in the previous application, PS=Ø® simplifies the structure and eliminates the additional expenses and architectural issues created by expansion joints.

Figure 7. Typical PS=Ø® Structural Expansion Joint Eliminated in in Steel Frame Structure with Concrete Floor